Which Is The Best Preheating Oven T8280 1600W

Nowadays, there are so many products of preheating oven t8280 1600w in the market and you are wondering to choose a best one. You have searched for preheating oven t8280 1600w in many merchants, compared about products prices & reviews before deciding to buy them.

You are in RIGHT PLACE.

Here are some of best sellings preheating oven t8280 1600w which we would like to recommend with high customer review ratings to guide you on quality & popularity of each items.

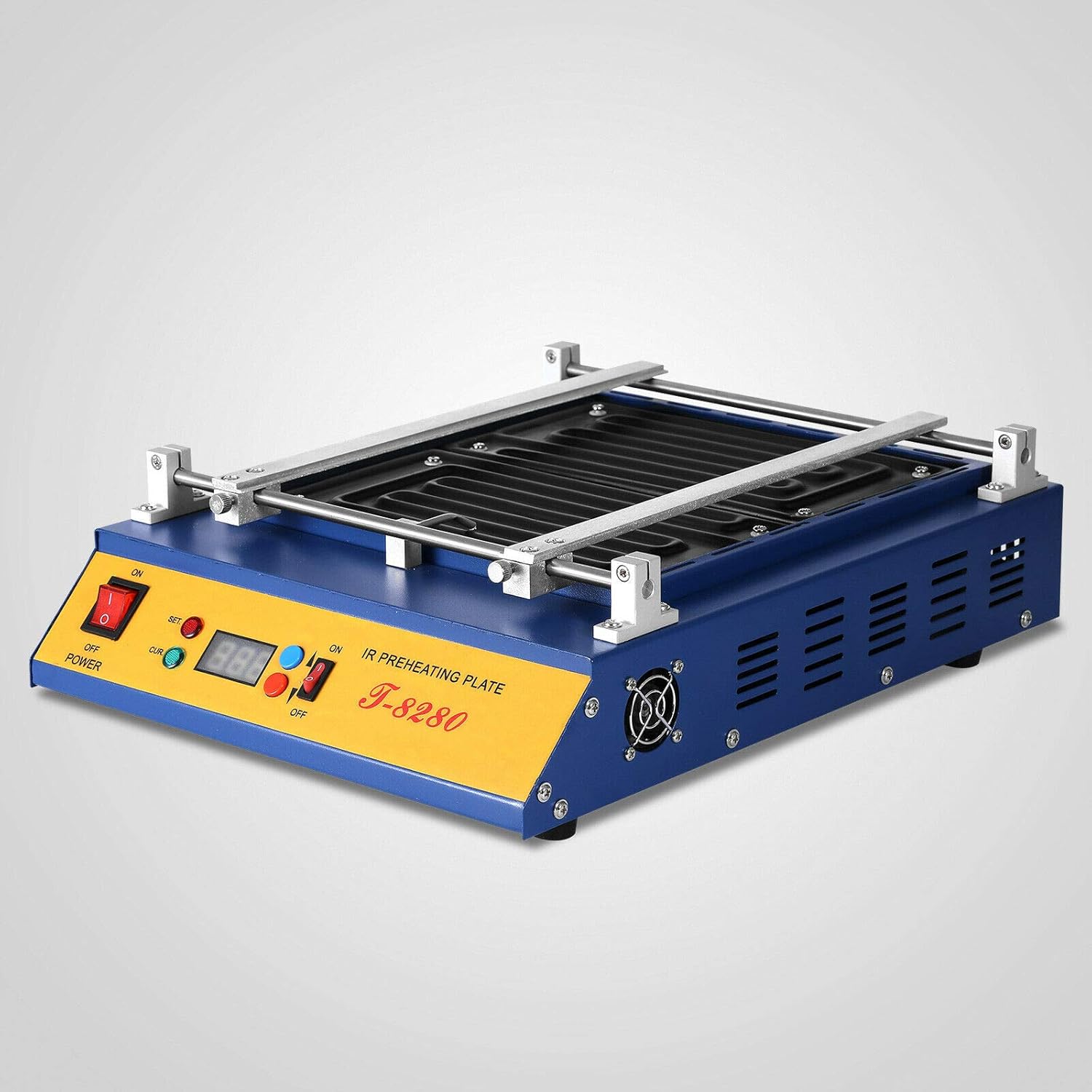

VEVOR Preheating Oven T8280 1600W Infrared Preheating Station Hot Plate PCB Preheater 280x270MM

- Preheating Station Work Bench Size :410x316mm

- Preheating Plate Size:280x270mm

- Complete Preheating Oven Machine Power :1600W

- Preheating Plate Power:1500W

- PCB Preheater Heating plate temperature can be adjusted: 0-450 degree

- Preheating Oven T-8280 Can Achieve To Heat PCB Board And Component Which Contains Lead Or Not,Especially For The BGA And SMD Parts

- Preheating Station Use Infrared Heat, Easy To Cut Through, Heat Proportion, Don’T Have Sirocco Flow. Don’T Shift The Small Components On The PCB Board,Ensure The Welding Quality

Hot Plate PCB Preheater Preheating Oven 1500W Soldering Station Welder

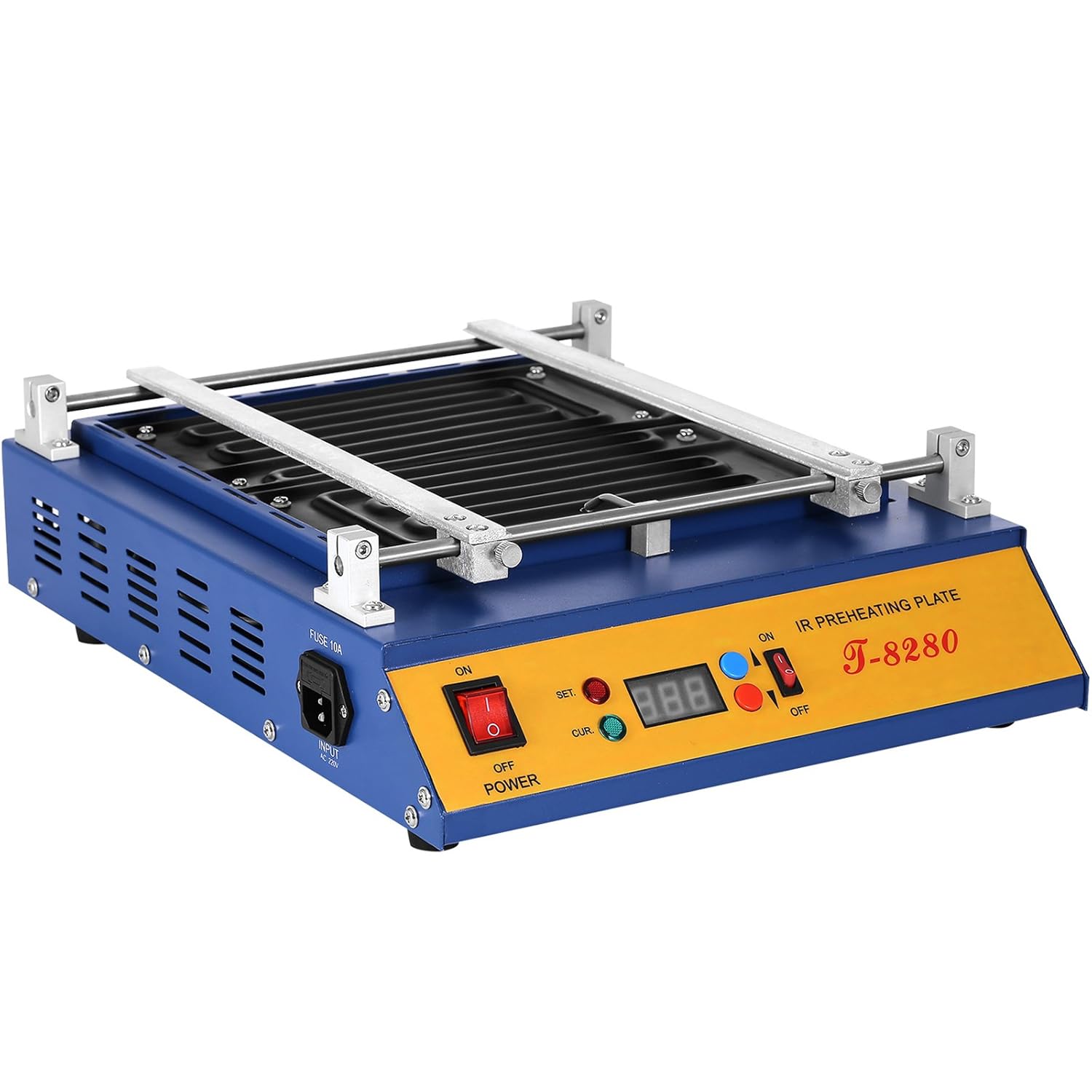

T-8280 selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely. It can achieve to heat PCB board and component which contains lead or not,especially for the BGA and SMD parts.

This item has 600W heating system, widely to 280x270mm. It is easy to operate, you can operate it through easy training.

Item Specification:

Working table size: 410mm x 316mm

Product size: 300 x 210 x 250 mm

Power: AC110V /50Hz

Complete machine power: 1600W

Preheating plate power:1500W

Preheating plate size:280x270mm

Heating plate temperature can be adjusted: 0-450 degree

Cautions:

1. After finishing, don’t turn off the power immediately; make sure the infrared preheating plate complete cooling.

2. Keep the ventilation free-flowing, the infrared preheating plate clean, use dehydrated alcohol clean it regularly!

3. The high temperature operation, pay attention, avoid scalding.

4. If you don’t use the machine for a long time, you’d better pull off the power source plug!

Package included:

1 X Desoldering heating station

1 X Power cable

1 X Insurance tube

1 X Crossflow fan

1 X User manual (compact disc)

Mandycng Circuit Board PLC Control Board IR-Preheating Hot Plate Station, Dual Current Voltage Benchtop Infrared Preheating Oven Plate 1.6KW Rework Station, Great for PCB BGA SMD Parts, Mobile Repair

- This item can achieve to heat the PCB board and component which contains lead or not, especially for the BGA and SMD parts.

- This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely.

- Use infrared heat, easy to cut through, heat proportion, don’t have sirocco flow. Don’t shift the small components on the PCB board, ensure the welding quality.

- This machine has a 600W heating system, widely to 280x270mm.

- Can use together with the handhold infrared welder T-835. Easily operate, you can operate it through easy training.

Description

This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely. It can achieve to heat the PCB board and component which contains lead or not, especially for the BGA and SMD parts. This item has a 600W heating system, widely to 280x270mm. It is easy to operate, you can operate it through easy training.

Specifications

- Work Bench Size: 16.14″×12.44″ (410×316mm)

- Rated Voltage and Frequency: AC 110V 60/50Hz

- Complete Machine Power: 1600W

- Preheating Plate Power: 1500W

- Preheating Plate Size: 11″×10.63″ (280×270mm)

- Preheating Plate Temperature Adjustable: 32℉ – 842℉ (0~450℃)

- Weight: 8kg

- Packing Size: 41x21x52cm

Package Content

- 1 x Preheating plate main body

- 1 x Temperature sensor

- 1 x PCB board holder

- 1 x Power line

LOVSHARE T8280 1600W Preheating Oven Adjustable 0-450 Degree Infrared Preheat Oven Welder Infrared Preheating Station Infrared Preheater

- Preheating oven voltage: 110V/50HZ. Complete machine power: 1600W.Preheating plate power: 1500W, preheating station work Bench Size: 16.1″ x 12.4″, Preheating Plate Size: 11″ x 10.6″. Preheating plate temperature adjustable: 0~450℃

- This infrared preheater selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- The preheating Oven can heat PCB board and component which contains lead or not, especially for the BGA and SMD parts

- Dedicated infrared heating, Strong penetration, Heat evenly, No hot air flow, Will not let the tiny components on the PCB shift, to ensure the quality of welding

- The machine is equipped with 1500W preheat (sol) system, preheat range 280x270mm / 11×10.6inch, can be used with hand-held infrared welding machine T-835

1600W Preheating Oven Adjustable 0-450Degree Infrared Preheat Oven Welder Infrared Preheating Station T8280 Infrared Preheater Item Specifications :

Worktable size: 16×12.5inch

Preheating plate size: 11×10.6inch

Rated voltage and frequency: AC110V 60 / 50Hz

Machine power: 1600W

Preheating plate power: 1500W

Temperature adjustable: 0-450 ℃

Instructions for use :

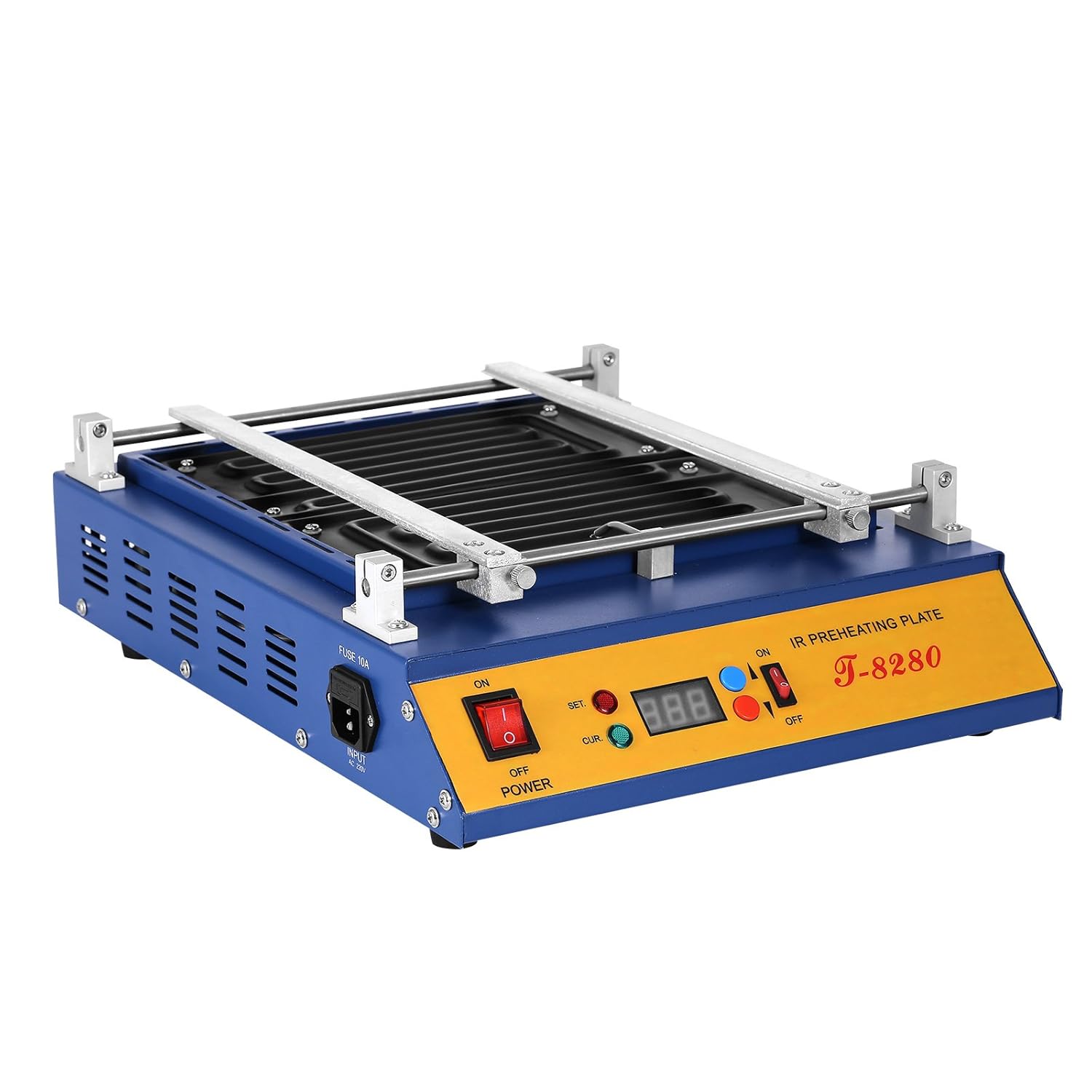

Depending on the PCB size, adjust the bracket position, place the PCB board on the bracket, tighten the fastening nut

Connect the power cord

Turn on the ‘power’ switch; self-test starts (the digital display will display the current room temperature)

Another small switch on the Front panel is for controlling the work of the infrared preheat chassis, press ‘on’ the infrared preheat chassis starts to work, press ‘off’, works end

According to the size of the PCB board and welding process requirements, press the blue button ‘▲’ and the red button ‘▼’ to adjust the infrared preheat chassis Output temperature (ranging in the 0-450 ℃)

Recommendations: For leaded PCB board preheating, adjustable infrared preheat chassis temperature to 100-120 ℃ or so; When preheating the lead-free PCB board, Adjustable temperature to 120-140 ℃ or so. Can also set a different preheating temperature based on the use craft and personal experience

After pressing the switch ‘ON’ to open the preheat chassis, waiting for 3-5 minutes, only if the display temperature is stable at or around the set value, then start the next step; when finished work, press ‘off’ to turn off the preheat chassis

Note: after working and turn off the preheat chassis; do not turn off the power switch immediately, please waiting for the unit fully cooled

Package Content

Preheating plate main body x 1

Temperature sensor x 1

PCB board holder x 1

Power line x 1

User manual x 1

OrangeA PCB Preheater 16×14 inch Infrared Preheating Station Hot Plate Preheating Oven1600W Soldering Station Welder (1600W)

- PCB preheater work bench Size: 410×316mm(16.14″×12.44″)

- Preheating plate size: 280×270mm(11″×10.63″)

- Infrared preheating station power: 1600w

- Preheating Plate Power: 1500w This preheating oven selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- Infrared preheating station power: 1600w

- Preheating Plate Power: 1500w

- This preheating oven selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- Soldering station can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts

IR Preheating Oven T8280 Rework Station Warm Up Pcb Board Preheating Plate

T-8280 selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely. It can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts. This item has 600W heating system, widely to 280x270mm. It is easy to operate, you can operate it through easy training

Feature:

This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

T-8280 can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts

Use infrared heat, easy to cut through, heat proportion, don’t have sirocco flow. Don’t shift the small components on the PCB board, ensure the welding quality

This machine has 600W heating system, widely to 280x270mm

Can use together with the handhold infrared welder T-835

Easily operate, you can operate it through easy training

Item Specification:

Work Bench Size: 410×316mm(16.14″×12.44″)

Rated Voltage and Frequency: 110v 60/50Hz

Complete Machine Power: 1600w

Preheating Plate Power: 1500w

Preheating Plate Size: 280×270mm(11″×10.63″)

Preheating Plate Temperature Adjustable: 0~450℃

Package Content

1 x Preheating plate main body

1 x Temperature sensor

1 x PCB board holder

1 x Power line

Similar items with 4 stars and above

L.HPT 1600W IR Preheating Oven T-8280 Rework Station Infrared Welder Warm up 0~450℃ Preheater 16×14 inch Infrared Preheating Station Hot Plate Preheating Oven Soldering Station Welder (T8280)

- PCB preheater work bench Size: 410×316mm(16.14″×12.44″)

- Preheating plate size: 280×270mm(11″×10.63″)

- Infrared preheating station power: 1600w

- Preheating Plate Power: 1500w This preheating oven selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- Infrared preheating station power: 1600w

- Preheating Plate Power: 1500w

- This preheating oven selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- Soldering station can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts

T-8280 Infrared IR PCB Preheater Preheating Oven 1600W 280 x 270 mm

Feature

This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely.

T-8280 can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts.

Use infrared heat, easy to cut through, heat proportion, don’t have sirocco flow. Don’t shift the small components on the PCB board, ensure the welding quality.

This machine has 600W heating system, widely to 280x270mm.

Can use together with the handhold infrared welder T-835.

Easily operate, you can operate it through easy training.

Specifications

Model: T-8280

Rated Voltage and Frequency: AC 220 V/50 Hz

Heat Style: infrared radiation

Complete Machine Power: 1600w

Preheating Plate Power: 1500w

Work Bench Size: 410×316mm(16.14″×12.44″)

Preheating Plate Size: 280×270mm(11″×10.63″)

Preheating Plate Temperature Adjustable: 0~450℃

Gross Weight:7 kg

Package Content

1 x Preheating plate main body

1 x Temperature sensor

1 x PCB board holder

1 x Power line

ZGYQGOO 1600W IR Preheating Oven T-8280 Rework Station Infrared Welder Warm up 0~450℃ Preheater 16×14 inch Infrared Preheating Station Hot Plate Preheating Oven Soldering Station Welder (T8280)

- ▼ PCB preheater work bench Size: 410×316mm(16.14″×12.44″)

- Preheating plate size: 280×270mm(11″×10.63″)

- ▼ Infrared preheating station power: 1600w

- Preheating Plate Power: 1500w This preheating oven selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- ▼ Infrared preheating station power: 1600w

- Preheating Plate Power: 1500w

- ▼ This preheating oven selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely

- ▼ Soldering station can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts

T-8280 Infrared IR PCB Preheater Preheating Oven 1600W 280 x 270 mm

Feature

This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely.

T-8280 can achieve to heat PCB board and component which contains lead or not, especially for the BGA and SMD parts.

Use infrared heat, easy to cut through, heat proportion, don’t have sirocco flow. Don’t shift the small components on the PCB board, ensure the welding quality.

This machine has 600W heating system, widely to 280x270mm.

Can use together with the handhold infrared welder T-835.

Easily operate, you can operate it through easy training.

Specifications

Model: T-8280

Rated Voltage and Frequency: AC 220 V/50 Hz

Heat Style: infrared radiation

Complete Machine Power: 1600w

Preheating Plate Power: 1500w

Work Bench Size: 410×316mm(16.14″×12.44″)

Preheating Plate Size: 280×270mm(11″×10.63″)

Preheating Plate Temperature Adjustable: 0~450;

Gross Weight:7 kg

Package Content

1 x Preheating plate main body

1 x Temperature sensor

1 x PCB board holder

1 x Power line

IR Preheating Plate T-8280 Rework Station PCB Board Temp-set Button 110V 1600W

1. This machine is with infrared component to

give off heat which independent exploration,

adopts advanced PID intelligent temperature,

controls temperature precisely.

2. T-8280 can heat PCB board and component

which contains lead or not,especially BGA

and SMD parts.

3. Use infrared heat, easy to cut through, heat

proportion, don’t have sirocco flow. Don’t shift

the small components on the PCB board,

ensure the welding quality.

4. This machine is with 1500W heating

system, heating area 280x270mm. Can use

together with the handhold infrared welder

T-835. 5. Easy operate, you can operate it after

simple training.

Item number:027026

ZOUQILAI 32LSingle Wall Oven Electric Multifunctional Under Counter Oven, Multifunctional Baking Cooling Down Fan in Stainless Steel Frame

- ◆ This oven uses a healthy enamel liner, power: 1600W, net weight: 7.8kg, voltage: 110V-240V, frequency temperature control: 50Hz.

- ◆ 32L capacity, to meet a single large amount of baking, temperature control mode: upper and lower tube independent, Control method: Electronic precision temperature control.

- ◆ APP smart recipes, one-click making delicious, mobile app network control, local recipes,Novices can easily make up-to-date cuisine.

- ◆ High-end sugar porcelain baked healthy non-stick oil, enamel liner, easy to clean and easy to clean the drill surface reflective back design, the energy lock temperature, better baking effect.

- ◆ Automatic preheating, let you feel peace of mind, humanized intelligent warm-up function, make baking more worry-free.

Feature:

Product Name: mini electric oven

Material: Enamel

Power: 1600W

Net weight: 7.8kg

Capacity: 32L

Voltage: 110V-240V

Frequency temperature control: 50Hz

Color Category: White

Temperature control mode: Electronic precision temperature control

Product size: outer size: length 50.2CM* width 38.7CM* height 30.75CM, inner cavity size: 36.3*31.7*26.9CM (1CM=0.39in)

T-8280 IR-Preheating Oven 110V/220V T8280 Preheat Plate 280270mm Infrared Pre-heating Station FOR PCB SMD BGA

- Easily operate, you can operate it through easy training.

- T-8280 can achieve to heat PCB board and component which contains lead or not,especially for the BGA and SMD parts.

- Use infrared heat, easy to cut through, heat proportion, dont have sirocco flow. Dont shift the small components on the PCB board,ensure the welding quality.

- This machine has 600W heating system, widely to 280x270mm/11.0*10.6in.Can use together with the handhold infrared welder T-835.

- This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely.

Work bench size:410x316mm/16.1×12.4in

Rated voltage and frequency:AC220-230v/AC110V 60/50Hz

Complete machine power:1600W

Preheating plate power:1500W

Preheating plate size:280x270mm/11.0×10.6in

Preheating plate temperature adjustable:0-450C

Main Components:

1xPreheating plate main body

1xTemperature sensor

1xPCB board holder

1xPower line

1xUser manual (compact disc)

2. Operation of preheating PCB board

(1) The placement and adjustment of the PCB board:

According to the size of the PCB board, adjust the PCB board holder, then put the PCB board and fix the adjust knob.

According to the size of PCB board and welding technological requirement, press the blue button (up)and the red button (down), regulate the output temperature of preheating plate between 0C and 450C

(2) Preheating open and close:

Press the “ON” button,open the preheating plate about 3-5 minutes, make the temperature be the setting value then carry on the next step .

Finishing, press “OFF”, the preheating plate stops working.

Attention:Dont close the power switch until the machine full cooling.

The preheating temperature set: If the PCB board contains lead, adjust the infrared preheating plate temperature to 100-120C;

if not, adjust to 120-140C.

You can also set the preheating temperature according to the users experience and technology.

Cautions

1. After finishing, dont turn off the power immediately; make sure the infrared preheating plate complete cooling.

2. Keep the ventilation free-flowing, the infrared preheating plate clean, use dehydrated alcohol clean it regularly

3. The high temperature operation, pay attention, avoid scalding.

4. If you dont use the machine for a long time, youd better pull off the power source plug

Conclusion

By our suggestions above, we hope that you can found preheating oven t8280 1600w for you.Please don’t forget to share your experience by comment in this post. Thank you!